EN / IEC 61368-1

CONDUIT SYSTEMS for CABLE MANAGEMENT

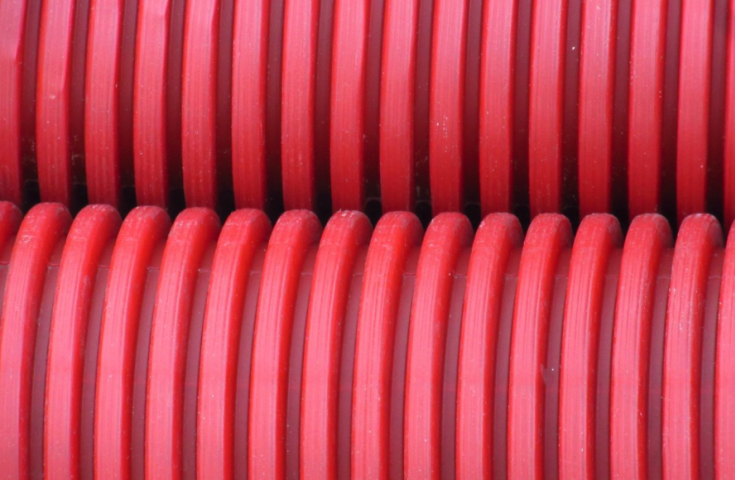

These are the systems used to prevent conductors passing current through pipe systems called electrical pipes to prevent environmental damage and protect the conductors from external impacts. Pipes are produced as insulator or metal.

To verify this system, it has been gathered under the title of 4 product groups in International standards. These are Rigid conduit systems (EN / IEC 61386-21), Pliable conduit systems (EN / IEC 61386-22), Flexible conduit systems (EN / IEC 61386-23) and Conduit systems buried underground (EN / IEC 61386-24). In order to verify the performance of the pipe systems, it is necessary to complete the type tests specified below positively. For pipe systems, it is necessary to classify the company declaration in general. The tests to be applied to the levels of the type tests will be the result of this classification.

These types of tests are listed below.

1.Classification:

6.1 According to mechanical properties

6.1.1 Resistance to compression

6.1.2 Resistance to impact

6.1.3 Resistance to bending

6.1.4 Tensile strength

6.1.5 Suspended load capacity

6.2 According to temperature

6.2.1 Lower temperature range

6.2.2 Upper temperature range

6.3 According to electrical characteristics

6.3.1 With electrical continuity characteristics

6.3.2 With electrical insulating characteristics

6.3.3 With electrical continuity and insulating characteristics

6.4 According to resistance to external influences

6.4.1 Protection against ingress of solid objects: protection in accordance with IEC 60529 to a minimum of IP3X

6.4.2 Protection against ingress of water: protection in accordance with IEC 60529 to a minimum of IPX0

6.4.3 Resistance against corrosion

6.5 According to resistance to flame propagation

6.5.1 Non-flame propagating

6.5.2 Flame propagating

|

Classification Type |

Classification Criteria |

|

|

6.1 According to mechanical properties |

6.1.1 Resistance to compression |

1. Level |

|

2. Level |

||

|

3. Level |

||

|

4. Level |

||

|

5. Level |

||

|

6.1.2 Resistance to impact |

1. Level |

|

|

2. Level |

||

|

3. Level |

||

|

4. Level |

||

|

5. Level |

||

|

6.1.3 Resistance to bending |

1. Rigid |

|

|

2. Flexible |

||

|

3. Flexible - Self gathering |

||

|

4. Non-flexible |

||

|

6.1.4 Tensile strength |

1. Level |

|

|

2. Level |

||

|

3. Level |

||

|

4. Level |

||

|

5. Level |

||

|

6.1.5 Suspended load capacity |

1. Level - Too light |

|

|

2. Level - Light |

||

|

3. Level - Mid |

||

|

4. Level - Heavy |

||

|

5. Level - Too heavy |

||

|

6.2 According to temperature |

6.2.1 Lower temperature range |

1. (+5°C) |

|

2. (-5°C) |

||

|

3. (-15°C) |

||

|

4. (-25°C) |

||

|

5. (-45°C) |

||

|

6.2.2 Upper temperature range |

1. 60°C |

|

|

2. 90°C |

||

|

3. 105°C |

||

|

4. 120°C |

||

|

5. 150°C |

||

|

6. 250°C |

||

|

7. 400°C |

||

|

6.3 According to electrical characteristics |

6.3.1 With electrical continuity characteristics |

|

|

6.3.2 With electrical insulating characteristics |

|

|

|

6.3.3 With electrical continuity and insulating characteristics |

|

|

|

6.4 According to resistance to external influences |

6.4.1 Protection against ingress of solid objects |

IP3X protection |

|

6.4.2 Protection against ingress of water |

IPX0 protection |

|

|

6.4.3 Resistance against corrosion |

|

|

|

6.5 Alev Yayılmasına Karşı Dayanıklılığa Göre |

6.5.1 Non-flame propagating |

|

|

6.5.2 Flame propagating |

|

|

2.Mechanical Properties Test:

Piping systems must have sufficient mechanical strength to complete the type tests positively. Type test is carried out according to the classification determined according to the declaration of the manufacturer. There should be no physical deterioration in the products during this type of experiments. The experiments given below for mechanical properties are carried out in order.

Compression Test; Type test is performed at the classification level selected according to the manufacturer's declaration. Samples prepared in the sizes specified in the standard before the experiment are compressed with the force specified at the classification level by the clamping device. Sample diameters are measured before and after the experiment. At the end of the experiment, cracks should not be seen in the sample and the diameter differences should not exceed 10% before the experiment.

Impact Test; The classification level is carried out in accordance with the manufacturer's declaration. The samples prepared before the test are conditioned in the cabinet with the test setup at the lowest temperature value at the specified level. After conditioning, impact is applied to the sample in accordance with the test level. Any cracks, fractures, etc. to complete this type of test positively. there should be no physical deterioration.

Bending Test; Type test is performed according to the sub-product standards of TS EN 61386-1 standard. The sample specified in the product standard is subjected to sample tests with the appropriate test setup. For the positive completion of this type of test, cracks, fractures, etc. at the end of the experiment. There should be no physical deterioration and it should be possible to pass through the gauge suitable for the diameter of the pipe.

Flexing Test; Type test is performed according to the sub-product standards of TS EN 61386-1 standard. The sample specified in the product standard is subjected to sample tests with the appropriate test setup. For the positive completion of this type of test, cracks, fractures, etc. at the end of the experiment. There should be no physical deterioration and it should be possible to pass through the gauge suitable for the diameter of the pipe.

Collapse Test; Type test is performed according to the sub-product standards of TS EN 61386-1 standard. The sample specified in the product standard is subjected to sample tests with the appropriate test setup. For the positive completion of this type of test, cracks, fractures, etc. at the end of the experiment. There should be no physical deterioration and it should be possible to pass through the gauge suitable for the diameter of the pipe.

Tensile Test; Type test level is selected in accordance with the manufacturer's declaration. The test specimen is prepared according to the sample specifications specified in the standard and the pipe and pipe fittings are subjected to pulling force by connecting to the appropriate test apparatus. Cracks, damage, etc. are required for the sample to complete the type test positively. there should be no physical deterioration.

Suspended Load Test; This type of test is carried out for pipe systems that are suspended. In accordance with the manufacturer's declaration, the sample suspended by the suspension means is tested at the highest temperature with the weight determined according to the declaration. In order to complete the type test positively, it should not have a deformation that would prevent its normal use.

3.Electrical Properties:

This type of test should be carried out after the external effects test. Piping systems should have sufficient electrical strength and insulation resistance in normal use.

Bonding Test; This type of experiment is applied only to metal pipe systems. Type test is carried out with the appropriate test setup and the resistance of the sample is measured. In order to complete the type test positively, the measured resistance must be less than 0.1Ω.

Dielectric Strength and Insulation Resistance Test; For the type test, the sample tip is placed in a 1 m high brine solution with approximately 100 mm outside. A saline solution is placed in the sample at the same level as the water level, so that the sample is conditioned for 24 hours. After conditioning, the experiment is carried out for 15 minutes at 2000 V with the appropriate test setup. In order to complete the type test positively, there should be no skipping during the experiment. Immediately after the dielectric test, the sample is immediately subjected to the insulation resistance test. Experiment is carried out at 500 V DC. In order to complete the type test positively, the measured insulation resistance must be higher than 100 MΩ.

4. Thermal Properties Test:

Non-metallic and composite pipes must have sufficient heat resistance. The declaration class for the heating test must be at the same level as in the compression test of the manufacturer firm. For the application of the type test, the declaration with the sample at the highest temperature level is placed inside the heating cabinet. The device is kept in the cabin with the sample for 4 hours. At the end of the period, the test device is removed from the cabinet with the sample and placed under the shaft in the device and the declaration is kept under load for 24 hours. In order to complete the type test positively, at the end of the experiment, breaking, cracking, etc. in the sample. there should be no physical deterioration and the appropriate gauge must pass through the pipe system.

5. Fire Hazard Test:

This type of test is applied to non-metallic and composite pipes. In accordance with the test TS EN 60695-2-11 standard, the glow wire test is applied at 750 0C. In order to complete the type test positively, the flame formed in the sample must be extinguished within 30 seconds.

After this experiment, a new sample prepared in accordance with the standard and a 1 kW flame test is applied in accordance with the TS EN 60695-11-2 standard. The test is carried out with the appropriate test setup according to the test time selected in accordance with the wall thickness of the pipe system. For the positive completion of the type test, the flame formed should be extinguished within 30 seconds, the silk paper at the bottom should not ignite and the resulting flame and redness should not be seen at 50 mm of the lower end of the upper clamp.

6.External Influences:

This type of experiment is carried out in accordance with the firm declaration using the methods specified in the TS EN 60529 standard. In accordance with the IP test protection class specified in the company declaration, an experiment is carried out on the sample that is assembled as in normal use. In order to complete the type test positively, it must be within the acceptance conditions specified in the TS EN 60529 standard.

7.Corrosion Resistance Test:

This type of test is applied to metallic or composite pipe systems. The level of experiment is selected according to the classification made in accordance with the firm's declaration. Piping systems are immersed in chemical solutions specified in the standard. Copper deposits and physical deterioration should not be present in the samples cleaned afterwards. The type test is considered to be positive if it satisfies these conditions.