IEC 61000-4-2 (Edition 2.0)

Electromagnetic Compatibility (EMC)- Part 4-2: Testing and measurement techniques - Electrostatic discharge immunity test

EMC Tests are tests that check the electromagnetic compatibility of a device or system. In the Electromagnetic Compatibility Test (EMC Test), it is aimed to operate any electrical and electronic device or system without being affected by and affecting other devices or systems in the environment. EMC Test is generally examined in two categories as Immune EMC Test and Emission EMC Test. Test limit values and test methods specified in the standards used in EMC Test applications may vary according to the features of the device or system.

Electrostatic Discharge (ESD) Test specified in IEC 61000-4-2 standard is one of the Electromagnetic Compatibility (EMC) immunity tests (EMC Test).

IEC 61000-4-2 standard covers the rules and test methods of electromagnetic compatibility immunity EMC tests for electrical and electronic devices that are exposed to static electricity discharges to the objects in direct contact with the operators and nearby.

The purpose of the IEC 61000-4-2 standard is to establish a common and repeatable basis for the evaluation of the working qualities of electrical and electronic devices exposed to electrostatic discharges.

Electrostatic discharge (ESD), one of the EMC tests specified in the IEC 61000-4-2 standard, is a high voltage event caused by the release of static electricity or electrical energy caused by electrostatic induction, and we can give examples from our daily life. Electrostatic discharge is an event that happens when you wear a thick woolen sweater and touch a metal area or get out of your car and touch a metal surface.

IEC 61000-4-2 standard, discharge current typical wave shape, test equipment, test level zone, test setup, test process are described.

Electrostatic Discharge (ESD) Immunity Testt:

Electrostatic Discharge (ESD) Immunity Test, which is one of the EMC Tests, evaluates the working qualities and performance of the device under test when exposed to static electricity discharges to the objects nearby by direct contact from the operators and by air.

While conducting the Electrostatic Discharge (ESD) Immunity Test (EMC Test), a ground reference plane is located on the laboratory floor and a minimum distance of 1 m is left between the device under test and the laboratory walls and any other metal structure.

The test setups may vary depending on whether the tested device is of the desktop or floor standing type. For devices standing on the ground, the tested device and cables are insulated from the ground reference plane with an insulating support of approximately 0.1 m thickness. For desktop devices, a table made of 0.8 m high wood is located on the ground reference plane. A horizontal connecting plane with dimensions of 1.6 m x 0.8 m is placed on the table. The tested device and cables are insulated from the connecting plane with an insulating support of 0.5 mm thickness. The tested device is placed at a distance of 10 cm from the horizontal connecting plane.

The test levels of Electrostatic Discharge (ESD) test which is one of the Electromagnetic Compatibility Tests (EMC Test) are as follows;

|

Contact |

Air |

||

|

Level

|

Test Voltage (kV) |

Level |

Test Voltage (kV) |

|

1 |

2 |

1 |

2 |

|

2 |

4 |

2 |

4 |

|

3 |

6 |

3 |

8 |

|

4 |

8 |

4 |

15 |

|

x |

Special |

x |

Special

|

|

"X" is a special level. This level should be specified in the device introduction. |

|||

For the application of Electrostatic Discharge (ESD) test, which is one of the Electromagnetic Compatibility Tests (EMC Test), by air, the ambient temperature should be between 15 ° C and 35 ° C and relative humidity should be between 30% and 60%. Static discharges are applied only to the points and surfaces that the device under test can reach during normal use of the staff, unless the discharge is directly applied to the device under test, or otherwise specified in product family standards.

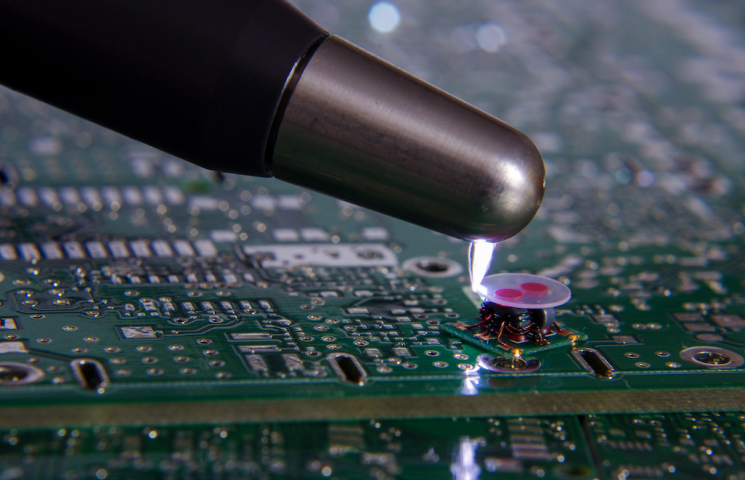

In direct applications; the pointed tip of the generator during contact discharge and the rounded tip of the generator during air discharge. In case of contact ejaculation, the pointed tip is touched to the device under test before operating the generator. In the case of air discharge, the round discharge tip is approached as quickly as possible (without causing mechanical damage) to touch the tested device, and after each discharge, the generator is removed from the device.

|

Round Tip: Used for air discharge. When the ends approach a conductive surface with a sufficiently large potential difference, a spark is formed.

|

|

Pointed Tip: It is used in discharging by contact. The leads are contacted to a conductive surface during the test, and the specified test voltage is applied.

|

In indirect applications; In the horizontal connecting plane, at least 10 discharges are applied opposite the center point of the device under test and at a distance of 10 cm from the front of the device. In the vertical connecting plane, at least 10 single discharges are applied to the center of a perpendicular edge of the connecting plane.